Vise Grip T Slot Clamp

- Product Title Vise Grip VGP9LN 9 Inch Long Nose Locking Pliers Average rating: 5 out of 5 stars, based on 2 reviews 2 ratings Current Price $23.10 $ 23. 10 List List Price $30.16 $ 30.

- Quick T-slot clamping of drill press vise I have a large floor drill press and vertical bandsaw with T-slotted tables. I often use Heinrich vises and would like to find a clamp or another hold down device that would allow quick locking and unlocking. Position the vise, lock it down to the table, drill a hole, unlock, move the vise, repeat.

Locking pliers (or Vise-Grips or a Mole wrench or a vice grip) are pliers that can be locked into position, using an over-center toggle action.

Toe clamps grip the side of the piece with significant positive down force without getting in the way. T-slot toe clamps do the same job, but are designed specifically to fit into the t-slots of machine tables. Find edge and toe clamps in a range of sizes, styles, edge surface types and materials.

History[edit]

The first locking pliers, named Vise-Grips, were invented by William S. Petersen in De Witt, Nebraska in 1924.[1]

In 1955 'Mole wrenches' were developed by Thomas Coughtrie (1917–2008), who was at that time managing director of M. K. Mole and Son.[2] The wrenches were manufactured in Newport, Wales, just off the M4, near to the Brynglas Tunnels; travelling west on the motorway, the Mole sign was visible immediately before entering the tunnels.

Mechanism[edit]

The principal mechanism of locking pliers is the over-centre clamp. When the pliers are closed on an object, the mechanism passes through a point of tightest clamping and as the handle levers are closed further, the jaws release slightly. The inherent flexibility of the pliers maintains a spring pressure on the jaws such that the handle needs to be pulled open to release the clamping pressure. Thus the pliers will safely remain clamped on the object without requiring continuous pressure on the handle levers.One side of the handle of locking pliers includes a bolt that is used to adjust the spacing of the jaws, the other side of the handle (especially in larger models) often includes a lever to push the two sides of the handles apart to unlock the pliers. 'Mole' and 'Vise-Grip' are trade names of different brands of locking pliers, yet mechanics and do-it-yourself hobbyists and craftspeople generically refer to locking pliers as 'Vise-Grips' in the US, and 'Mole grips' in the UK. In Ireland the tool is known as a 'vice grip'.

Locking pliers are available in many different configurations, such as needle-nose locking pliers, locking wrenches, locking clamps and various shapes to fix metal parts for welding. They also come in many sizes.

Operation[edit]

The bolt is used to set the jaws to a size slightly smaller than what is to be gripped. The jaws are then closed on the gripped object.

Because of the lever action the jaws move only slightly but with much force. Locking pliers have four advantages:

- Their lever action is stronger than that of ordinary pliers, so they can apply much more force;

- Even though they can apply more force, they do so in a very controlled manner; this is because the jaws will never close beyond the set point;

- The closing point and with it the force that is applied on the gripped object can be finely controlled;

- When they are closed they remain closed on their own without any user intervention.

A typical use would be to hold metal parts in place for welding. They are also used for holding a nut or bolt that has been 'rounded'; pulling out nails; holding pipes without squeezing them; or as temporary levers/knobs on equipment and machinery.

References[edit]

- ^'Petersen Manufacturing'. Official Nebraska Government Website. Retrieved 2012-03-21.

- ^[1]

External links[edit]

| Wikimedia Commons has media related to Locking pliers. |

- 'New Tool Is Both Pliers and Wrench'Popular Science, December 1935, page 42

- 'Wrench with Vise Like Grip Keeps Work from Slipping', Popular Mechanics, September 1935, page 326

This article is from Issue 70 of Woodcraft Magazine.

Transform any work surface into an apprentice with these off-the-shelf solutions

One of the first things you learn about woodworking is that many tools aren’t terribly useful by themselves. Just as a tablesaw needs a rip fence, and a router requires a guide of some sort, workbenches and assembly tables need help in order to hold stock for machining and assembly. Although woodworkers will continue making dogs, stops, and clamps, store-bought accessories offer some advantages that aren’t found in shop-made counterparts.

To make sense of the latest batch of workbench workmates, I built a test bench and put these accessories through their paces. (This MDF platform worked so well, it’s found a permanent spot in our shop.)

As you’ll see, each system has strengths that give it an edge for certain applications. The most surprising discovery was how well these lightweight hold-downs double as a bench vise. You may not want to cast off your cast-iron vise, but if you don’t own a full-fledged workbench, or want to get more work from a countertop, sawhorse, or spare table, then read on.

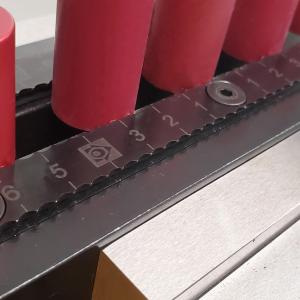

Better than an extra pair of hands. Kreg’s Klamp Trak and Automaxx Klamps work together to hold joints flat and flush for fast and efficient assemblies.

Kreg’s Trak & Klamps

Kreg’s new clamping system may be the easiest way to turn a basic assembly table (or tablesaw extension table) into a multi-function work surface for sanding, routing, and of course, pocket-screw joinery.

The system’s foundation is based on flush-mounted tracks and plates. The plates are mortised in place and offer a single anchor point. The tracks provide more positioning options for Automaxx Klamps and guide blocks. To inset the 0.695'-thick tracks, simply position them on adjacent sides of a piece of 3⁄4' MDF, as shown above.

For vise-like versatility, bolt a Klamp Vise to the edge of your bench, with an Automaxx Klamp in the slot, as shown below.

The only shortcoming with these clamps is that they’ll only mount on the proprietary tracks or plates. According to Kreg, the clamps were designed with 5⁄16' heads because clamping pressure can deform lighter-gauge 1⁄4' T-tracks.

A versatile vise substitute. Kreg’s Klamp Vise consists of a 10'-wide steel plate with a pair of 5⁄16' T-slots that accommodate an Automaxx Klamp. The clamp’s pressure withstands planing and sanding chores, but its 2' range requires closely-spaced dog holes. Pairing the clamp with bench dogs and guide blocks keeps parts from shifting.

In-line line-up. A side-by-side comparison reveals some of the strengths and weaknesses of these dog hole clamps.

While Armor’s features make it a tall order; Lee Valley’s bench-hugging Bench Blade has a limited clamping range.

In terms of clamping range and bench height, the Wonder Pup fits in the middle of the pack.

Low-profile pairing. With a few well-placed dog holes, stops can work with little clamping pressure. Projecting just 0.22' above the benchtop, these planing stops are particularly well suited for planing and scraping thin parts.

Even with good bench vises, you’ll often need an extra hand. In-line clamps, partnered with single-post dogs or double-post stops can be positioned anywhere you can drill a 3⁄4'-dia. hole.

When choosing a set, consider the clamp’s range and height as well as its clamping pressure.

Armor’s sliding push rod design wins points for long reach and adjustable force, but the 23⁄8'-tall body can interfere with planing and sanding. On the other extreme, Lee Valley’s Bench Blade is least likely get in the way, but the sliding jaw reaches just 1⁄4'. Veritas’ Wonder Pups (and larger Wonder Dogs), offer a middle ground. The 5'-long threaded rod is slower to adjust than the Armor’s rod, but the pup’s post protrudes just 7⁄8' above the bench without the O-ring spacer.

Hold-downs that hold their own. The Armor and Lee Valley deliver more than enough clamping pressure for hand and power tool work. The key to a solid grip is a thick top. If your bench is less than 11⁄2' thick, either add a layer of MDF or attach a dog bracket (photo below).

Before the age of metal vises, woodworkers relied on hold-downs for holding work to their benchtops or against the side skirts. Clamping doesn’t get much easier: drop the post into a hole, and then give the hook at tap. To release, they’d rap on the back. This clamp fell out of favor when modern reproductions lacked the proper hook to hold work securely. Also, some of the cheaper copies would crack when tapped. Today, you can find premium hand-forged holdfasts, but the evolved versions shown here more than hold their own. The big benefit? Neither requires a mallet.

Despite outward appearances, the Armor Auto-Pro Horizontal and Veritas Fast-Action hold-downs work in a similar manner: slide the post into a dog hole until the pad touches the work, and then throw the lever to cinch the clamp and wedge the post in place.

Lee Valley’s cam lever provided as much pressure control as Armor’s high-tech auto-adjust clamping mechanism.

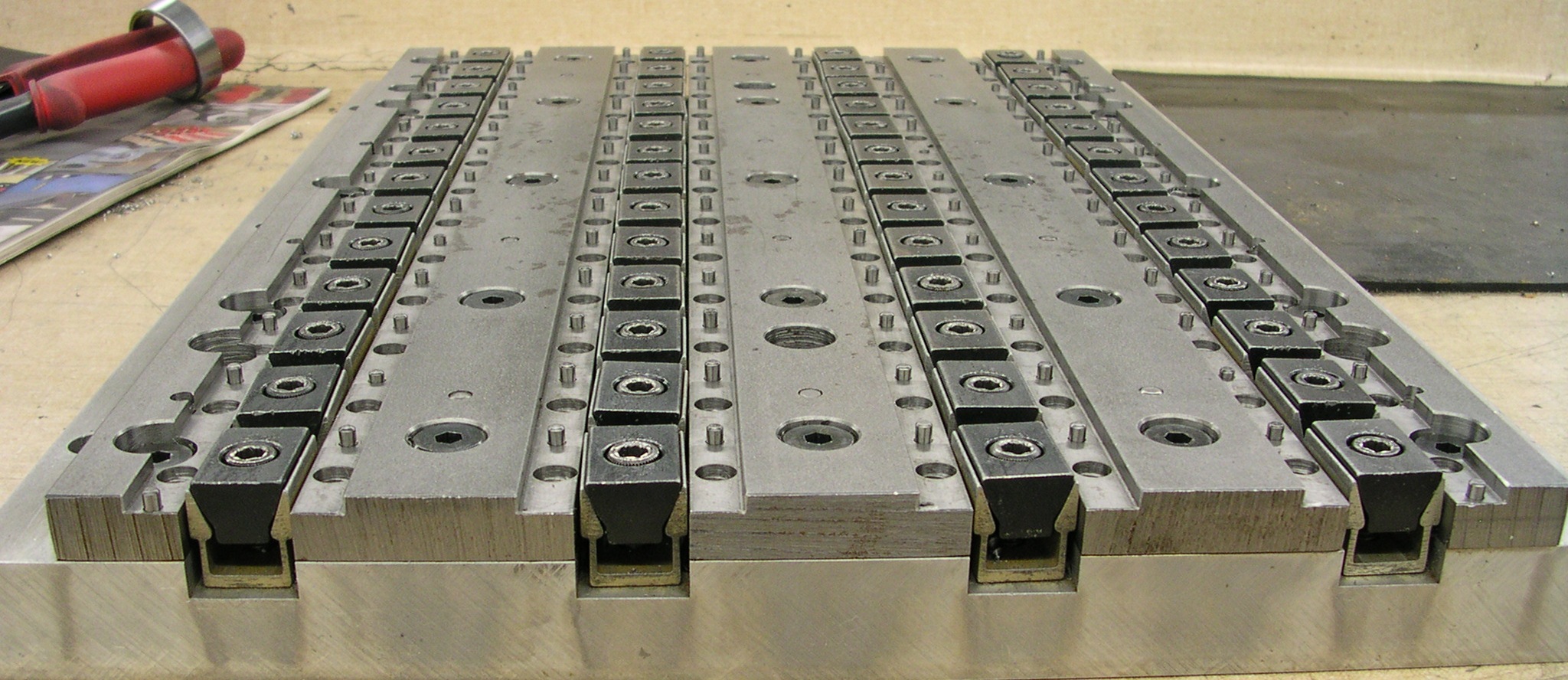

Mini Vise Grip Clamps

The holes have it. A few rows of 3⁄4'-dia. holes offer tons of positioning options for Armor’s clamps and fences. For a vise-like grip, partner the hold-downs with a dog bracket.

Vise Grip T Slot Clamps

The Armor Advantage

Armor’s Auto-Adjust clamping mechanism may be revolutionary, but I think the best thing about Armor’s system is how easy it is to transform a simple slab into a workbench. Drill a few rows of 3⁄4'-dia. holes and you’re set. Optionally, you can attach a dog bracket (available in 4' and 12' lengths) and pair it with clamps to make a decent, lightweight vise. While Lee Valley’s low-profile stops are better suited for planing, Armor’s taller stops provide a super stable platform for supporting wide boards, panels, and doors.